An ultra-strong future

10.10.2018. At this year’s EuroBLECH, the world’s largest exhibition for the sheet metal industry (23 to 26 October in Hanover), Stahlo is offering an exclusive first look at its new plant in Gera, Germany. Visitors to the company’s stand (E78 in hall 17) can view a physical 3D model of the facility and its state-of-the-art production logistics and IT technologies. The focus is on high-quality machining and processing of high-strength and ultra-high-strength steels.

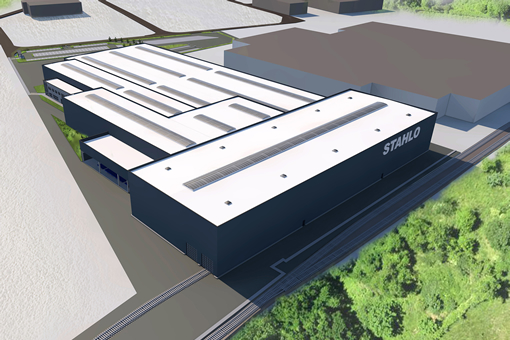

Stahlo is expanding its ultra-high-strength steel capabili-ties by establishing a new plant in Gera with a 22,000 m2 production hall. Operation is slated to commence in early 2019. In particular, it will employ a new, second slitting line for steel coils of up to 1900 MPa to process as many as 60 strips in a single operation.

Unparalleled in Europe

Stahlo, one of Germany’s largest mill-independent steel service centres, has its sights set on technology leader-ship in this market – and this expansion underlines its ambitions. Guido Spenrath, Managing Director of Stahlo, underscores: “This is unparalleled in Europe. In future, we will be able to process master coils up to 1850 mm wide on the input side, and create slitted coils 16 mm in width on the output side, all in a single operation.” The Gera facility will have production capacity of approximately 400,000 metric tons, and will manufacture products ranging from slitted coils, to cut-to-size blanks, trapezoids and contoured blanks. Stahlo is investing a total of 45 million euros in the plant.

In addition to the second slitting line, the steel service centre is adding resources for cutting contoured blanks. Specifically, the Gera plant will soon gain a second, state-of-the-art blanking line. This will not only process steel, including stainless grades, but also aluminium.

Stahlo recognised the significance of high-strength and ultra-high-strength steel at an early stage – meaning the enterprise has in-depth experience and end-to-end expertise, from receiving input materials to machining, to packaging. This gives Stahlo a decisive advantage, particularly as there is a shortage of skilled workers in this segment.

Moreover, Stahlo has prioritised efficient plant configura-tion, including its logistics processes. A largely autono-mous crane and an automated coil warehouse help ensure the seamless flow of materials.

Quality control in real time

Outstanding quality control is integral to all Stahlo processes, and the steel service centre is certified to IATF 16949. In the in-house laboratory, Stahlo’s special-ists assess mechanical and chemical properties. Non-contact inline measurement systems verify that products remain within defined tolerances.

IT is also key to the new plant’s performance. In future, the majority of operations will be automated – and process and machine data will be continuously captured.

Early recognition of trends

Stahlo was quick to recognise the potential of processing high to very high-strength steels. Since 2004, the enterprise, a subsidiary of the Friedhelm Loh Group, has processed ultra-high-strength steels with a tensile strength of up to 1400 MPa in Gera. The facility currently includes lines for slitting and for cutting contoured blanks – and latter is one of the largest and most advanced mill-independent centres in Europe. Both lines can process high-strength steels, and can produce the high quality required for automotive outer body panels.

Telephone: +49(0) 2772 505 - 2527

E-mail: unternehmenskommunikation@friedhelm-loh-group.de

Downloads:

Press release (PDF, 324 KB) Image 1 (JPG, 0,718 MB) Image 2 (JPG, 0,808 MB)

Image 1: Equipped for future challenges: Stahlo’s new plant in Gera-Langenberg, Germany, will feature a 22,000 m2 production hall.

Image 2: Guido Spenrath, Managing Director of Stahlo.